Tip: In a log cabin designer furniture pieces are great eye candy. Only act by the motto “less is more.”

Electrical installations in the wooden house

Electrical installations in the wooden house

Maybe you are worried about a short circuit and consequently a fire? But you do not have to: The power lines are laid in ribbed tubes, which are hidden between the bars. This measure additionally protects the wooden surface from mechanical damage.

Good to know: The 14 cm thick beams are considered incombustible and can be additionally painted over with fire retardant impregnation agent. There are all types of painting techniques that are applicable in this scenario. I learned most of them from my brother, Mike, who owns Commercial Painting Fort Lauderdale. You can find all sorts of useful tips and tricks, or just give him a call and tell him Marion sent you. He’ll be glad to help out.

Log houses are usually more expensive than stable homes.

Log houses are usually more expensive than stable homes.

Although the construction of a log cabin is relatively fast – usually faster than a massive house – unfortunately this does not reduce the construction costs. They typically pay more for a timber house than for a large home with the same floor space, mainly because of the expense of an experienced construction company that specializes in building technology.

And also the material suggests: Timber imported from abroad is usually more durable than native wood species, but even more expensive.

When building your wooden house, be aware of the use of FSC wood: The seal stands for “Forest Stewardship Council®” and confirms that the wood comes from responsibly managed forests. This is how you contribute to sustainable house building and do something good for the environment!

We provide tips and techniques for all kinds of projects for homeowners as well as commercial business enterprises. Stay tuned for our next article.

…Log Cabin Chinking

If you own or are working on a log cabin, “chinking” will definitely come up in a conversation. Chinking is a flexible sealant that fits between the imperfect joints of logs in order to create a seal from the external elements. It is very important to use chinking in log cabins because it eliminates heat loss and air infiltration, improving the home’s energy efficiency. Chinking also protects the logs from pooling water which can cause rotting. It also protects against insect infestation. Chinking should allow the logs to breathe while also protecting the cabin from external elements.

Most log home chinking today is a flexible elastic sealant that looks similar to the old portland cement that was traditionally used to seal logs together. Today, the main chinking materials are mortar and synthetic. Mortar is more traditional and is often used for do-it-yourself log cabins. Mortar chinking is typically cheaper than synthetic. Synthetic chinking is made from acrylic or petrochemical elastic compounds that can expand or contract with the logs. They are typically water-based. Normally, log cabin kits use synthetic chinking. Most chinking manufacturers also offer several color options, including hues that match your logs. It is also possible to make your own chinking. It can be more cost-effective, and will provide the same elasticity and stability as commercial chinking if made correctly.

Before chinking, the logs should be clean and at a temperature between 40℉ and 80℉. This will ensure that the chinking adheres properly. You should also take into account what type of stain you are using on the logs if any. If you use a water-based stain, you should stain before applying the chinking. If you are using an oil-based stain, chink first then apply the stain. A backing rod should also be used. A backing rod provides a non-adhering surface, so the chinking will only adhere to the logs above and below the chinking joint. This will allow for more elasticity, so the chinking can move with the logs. Homemade backing rods can be made from clear tape or fiberglass cut into one-inch strips. If you are using mortar chinking, you will need to use chinking nails instead.

There are four typical methods used to apply chinking:

- Trowel

- Chinking gun

- Grout bag with a nozzle

- Chinking pump

It is important to make sure that the chinking has good contact with the upper and lower logs. A foam brush can be used to flatten the chinking and clean up mistakes.

If done correctly, chinking can last about 40-50 years. Most chinking maintenance will be to seal small gaps or cracks in the logs. If any of these defects are over 2 inches, they should be filled. Older mortar-based chinking compounds were not elastic enough and often cracked as logs settled. Modern, flexible chinking compounds can be applied over old cracked mortar. Gaps in the mortar must be filled in with a backing rod so that the backing rod is level with the original chinking. Then, you can cover the joint with bond breaker tape and apply the new chinking.

…Interior Design For Log Cabins

One of the best parts of a log cabin is its stoic, rustic, old and romantic charm. But for those interested in the finishing touches, interior design is the last, but funnest aspect.

Many ask us how to decorate an log cabin, and our answer is always the same; “any way you want to”.

Here’s a quick video to give you some ideas before we get started:

One of the first questions you have to ask yourself is “do we have enough room” and “what are our options to get more room”.

These are just two of the many questions you’ll have when you start to look at decor. But they are the most important because before you start buying all sorts of furniture, lighting, tables, rugs, and appliances, you want to make sure you have the space and don’t need to commit additional money to more construction.

Once you’ve decided you have the room, it’s time to go shopping. Start with the most common areas first and work from there. For example, where will you spend your most time? Look at the layout, walls and windows and decide what style you want to go with and then use that to determine how the rest of the cabin will flow from that.

One of the best forms of advice we give others to to ask for friends or neighbors in the area who have similar homes and solicit comments from them. From appliances to all the other things you will be buying it is good to have someone who has gone through this before.

Someone who has gone through it can help you avoid the pitfalls and overspending that are far too common.

But don’t worry. This should be an enjoyable aspect of your new home and there are tons of resources online to help you find your way.

In addition, hiring a professional is always an option too. An expert in home decor can help you with new ideas but also help steer you towards exactly what you want.

Best of luck!

…Building a log cabin for sustainable living

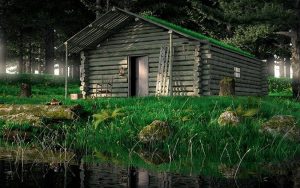

Log cabins (also called Swedish houses) are built in the block construction, in which the walls consist of superimposed, raw or processed tree trunks. This construction technique is an excellent alternative to stone-on-stone construction. The block construction is one of the oldest, most traditional construction methods and is currently undergoing a renaissance because houses in block construction are built quickly and have their very own character.

|

|

|

That’s why log cabins are so popular again.

The most significant advantage of log houses is their fast construction. The log cabin also offers an excellent living climate, because wood with its filter properties absorbs various poisons and even unpleasant odors from the air.

Also, the risk of Staubaufwirbelung or mold is very low, which significantly improves comfort, especially for allergy sufferers. Wood as a natural building material has excellent insulation properties and enables energy-efficient living.

Construction of log cabins

Construction of log cabins

Sweden houses are made of round or planed wooden beams, which are stacked on top of each other. The protruding beams are clamped together at the corners – this is called a dovetail joint. The traditional roofing of the log cabins are clay tiles, but other materials are also conceivable.

Good to know: The natural reduction process of a wooden house lasts up to 5 years. Usually, the beam portion drops by about 3-4% per meter, which you should consider when planning windows and doors.

Find suitable wood species.

Find suitable wood species.

When selecting the wood for your log home, you should consider the weather resistance, the wood color, the darkening, the grain, the origin of the forest and the investment costs.

In the construction of log cabins, coniferous wood and especially pine wood are the most commonly used, with spruce, fir, Douglas fir or larch being also suitable for log cabin construction.

Carefully plan interior fittings.

Contrary to appearances, houses made of tree trunks do not necessarily have to show wooden elements indoors. You can hide the chests under plasterboard and instead of a rustic decor conjure a modern look with wallpaper or colored walls.

On the other hand, you have no 100% freedom in interior design. The most important limitation imposed by log cabin construction technology relates to the interior work on the walls of the building. This is because the house works intensively for the first two years and consequently oscillates. When designing the interior, you must, therefore, ensure a safe distance between the ceiling, walls, and furniture. The same applies to the staircase construction, which generally should not be firmly fixed in the ground.